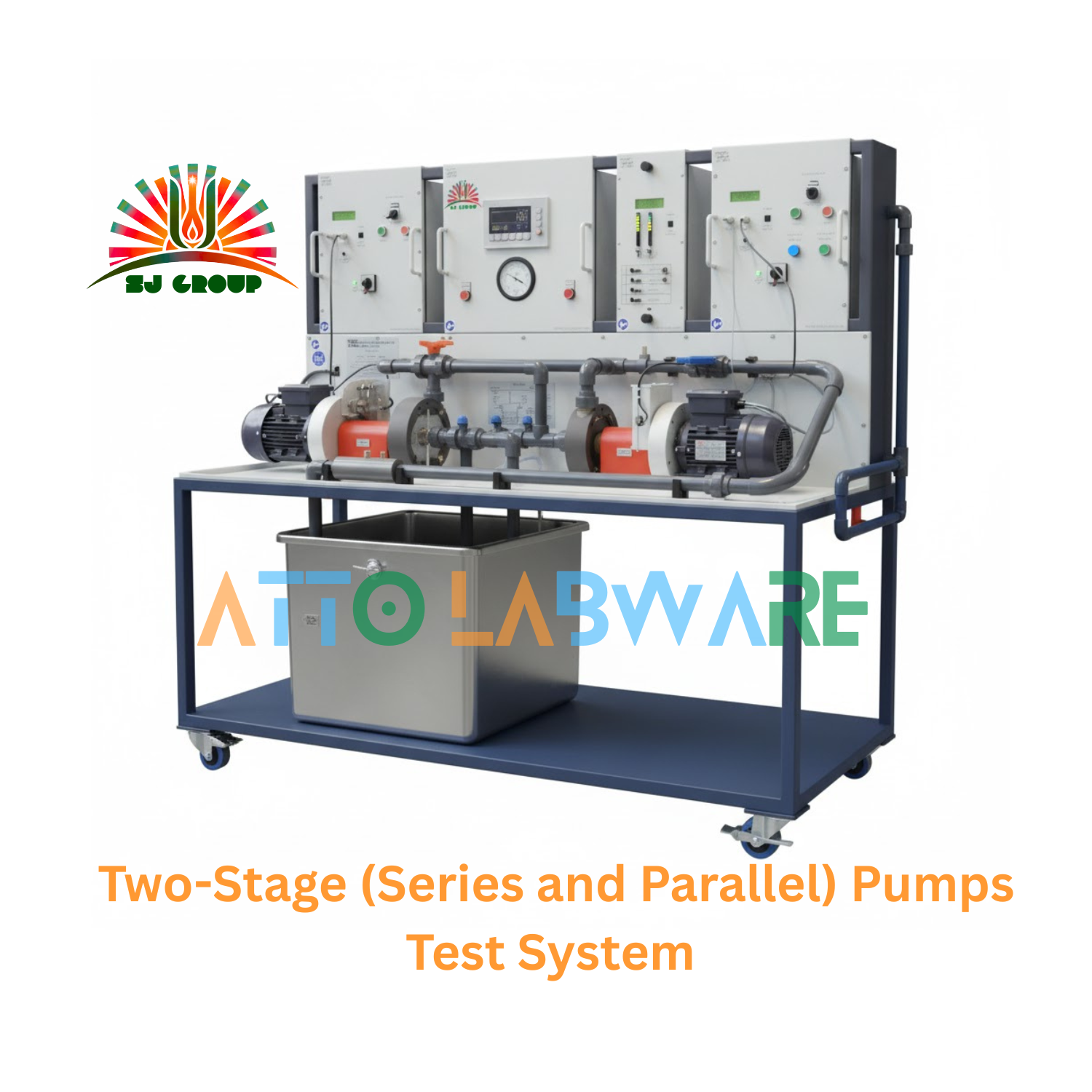

Two Stage (Series and Parallel) Pumps Test System

The Two Stage (Series and Parallel) Pumps Test System by Atto Labware is a comprehensive training unit designed to study the performance characteristics of centrifugal pumps when operated as two-stage (series) and parallel configurations. This apparatus demonstrates how connecting pumps in series increases head, while parallel operation increases discharge, allowing students to understand the combined performance of multi-pump systems used in industrial and hydraulic applications.

Educational Objectives

Students and researchers will be able to:

-

Demonstrate the performance of pumps connected in two-stage (series) and parallel configurations.

-

Plot characteristic curves of head, discharge, and efficiency for each mode.

-

Compare energy input, head rise, and flow rate between single, series, and parallel operation.

-

Verify theoretical performance relationships for multiple pump systems.

-

Understand applications in multi-pump water supply and process systems.

Performance Measurement

-

Measurement of suction and delivery pressures for each pump.

-

Determination of flow rate using rotameter or volumetric tank.

-

Input power measurement using a digital wattmeter or energy meter.

-

Calculation of head, discharge, power, and efficiency for different configurations.

-

Comparison of experimental results for single, series, and parallel operations.

Panel and Instruments / Components

-

Centrifugal Pumps (2 Nos.): Identical single-stage pumps mounted on a common base.

-

Drive Motor: 1 HP, 230 V AC motor with flexible coupling to both pumps.

-

Valves and Piping: Provided for easy configuration between single, series, and parallel modes.

-

Flow Measurement: Rotameter or calibrated measuring tank.

-

Pressure Gauges: Bourdon type or digital sensors on suction and delivery lines.

-

Water Reservoir: Supply and return tanks with drain valve.

-

Control Panel: Equipped with digital energy meter, switches, and safety devices.

-

Frame Structure: Rigid, powder-coated steel with vibration damping supports.

Specifications (Includes Technical Data)

| Feature | Detail |

|---|---|

| Type | Two-Stage Pump Performance Apparatus |

| Pump Type | Centrifugal Pumps (Identical) |

| Number of Pumps | Two |

| Pump Rating | 0.5 HP or 1 HP each |

| Motor Speed | 2800 RPM (Typical) |

| Flow Range | 0 – 25 LPM |

| Head Range | Up to 25 m (Combined in Series) |

| Pressure Measurement | Bourdon Gauges / Digital Pressure Sensors |

| Flow Measurement | Rotameter / Volumetric Tank |

| Power Measurement | Digital Wattmeter / Energy Meter |

| Working Fluid | Water (Closed Loop System) |

| Power Supply | 230 V AC, Single Phase, 50 Hz |

| Frame Material | Stainless Steel and Powder-Coated Steel |

| Dimensions | 1600 mm L × 600 mm W × 1000 mm H |

| Weight (Approx.) | 70 kg |

Note: Optional data acquisition and analysis software available for real-time pump performance monitoring.