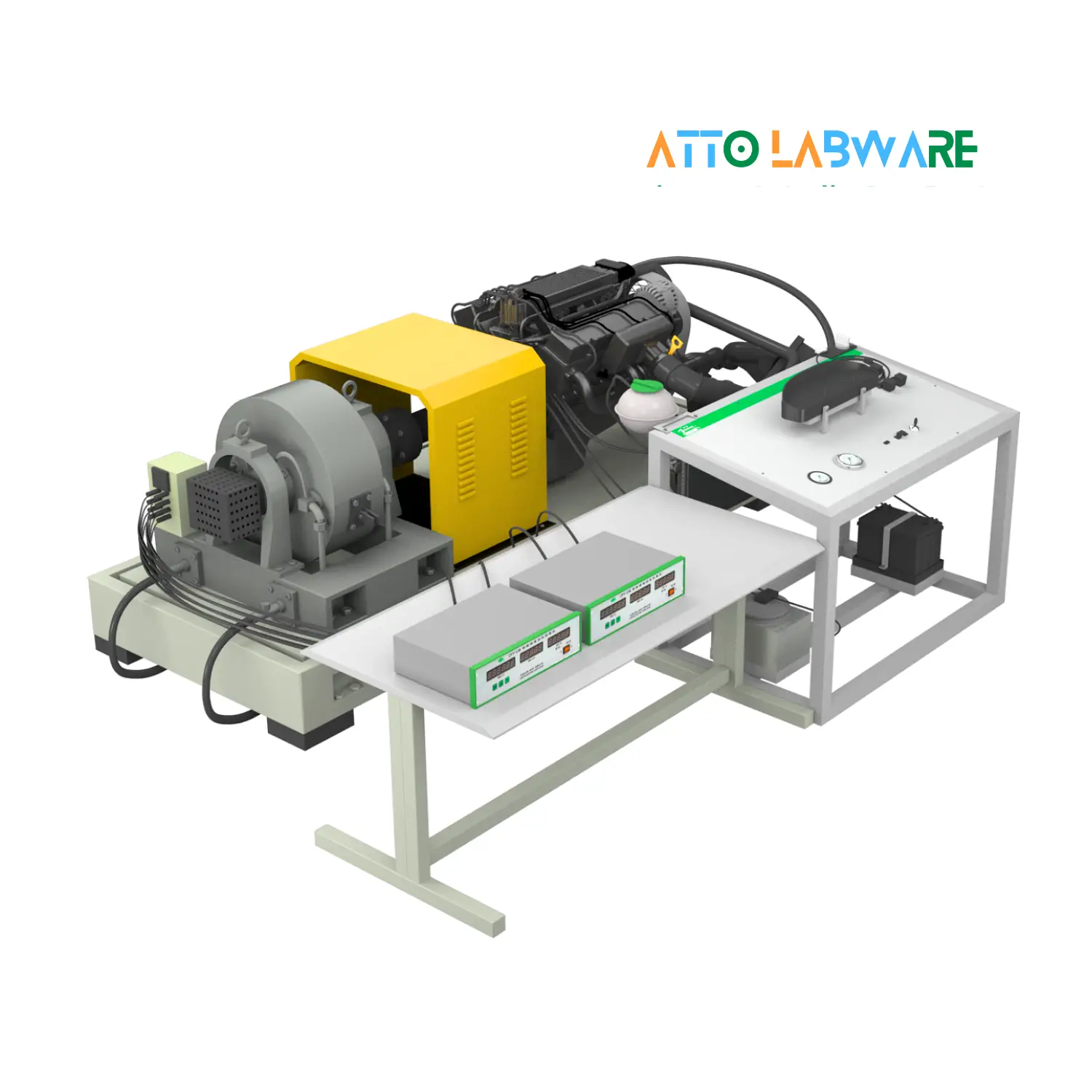

The Gasoline Engine Test Rig, manufactured by Atto Labware, is an advanced training system designed for studying the performance characteristics of gasoline (petrol) engines. It enables hands-on learning of engine testing, performance measurement, and efficiency evaluation under controlled laboratory conditions. The rig is mounted on a mobile workstation with integrated safety and measurement systems, making it suitable for universities, technical institutes, and automotive training centers.

Educational Objectives

Students will be able to:

-

Understand the construction and operation of gasoline engines.

-

Measure and analyze engine torque, speed, power, and efficiency.

-

Conduct performance tests at different loads and throttle positions.

-

Study the influence of air-fuel ratio, ignition timing, and load variation.

-

Perform heat balance tests and determine specific fuel consumption (SFC).

Performance Measurement

-

Measurement of torque and brake power with a dynamometer.

-

Calculation of thermal efficiency and mechanical efficiency.

-

Measurement of fuel consumption rate and air intake.

-

Recording of temperature, exhaust gas, and cooling water parameters.

-

Plotting of performance curves (power vs. speed, efficiency vs. load, etc.).

Panel and Instruments / Components

-

Gasoline engine (single-cylinder or multi-cylinder, as per configuration).

-

Dynamometer (eddy current, hydraulic, or mechanical loading).

-

Fuel measurement unit with burette/digital flow meter.

-

Air intake measurement unit with orifice and manometer.

-

Temperature sensors at exhaust, cooling water, and engine points.

-

Digital meters for RPM, torque, voltage, and current (if generator coupled).

-

Control panel with indicators, protective devices, and emergency stop.

-

Mobile workstation with protective guard enclosures.

Optional Software Package

The system can be supplied with dedicated software to:

-

Record and display engine operating parameters.

-

Plot real-time performance curves automatically.

-

Perform heat balance calculations.

-

Provide data logging and reporting tools for classroom analysis.

⚡ Manufacturer: Atto Labware

Note: Customized specifications and software are available on request.