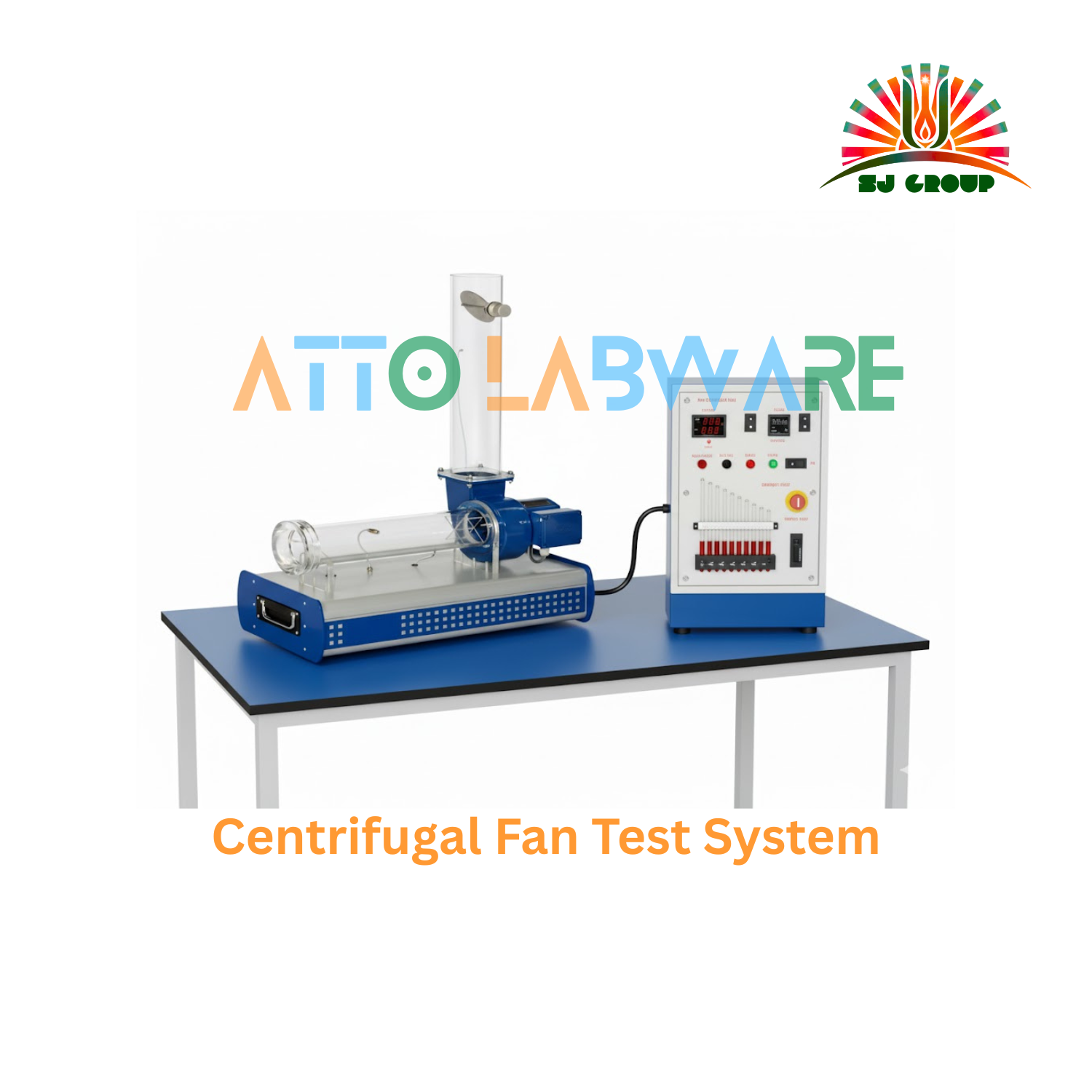

Centrifugal Fan Test System

The Centrifugal Fan Test System, manufactured and supplied by Atto Labware India, is a fundamental machine intended for studying the aerodynamic and mechanical performance of air-moving equipment. It is designed to demonstrate key concepts related to airflow, pressure development, power consumption, and efficiency under varying speed and load conditions. This system is essential for Mechanical, HVAC (Heating, Ventilation, and Air Conditioning), and Aeronautical engineering laboratories.

Educational Objectives

Students and researchers will be able to:

- Determine the Head (H) (static, velocity, and total pressure) developed by the fan.

- Measure the Mass Flow Rate (Q) of air handled by the system.

- Construct the Fan Characteristic Curves (H vs. Q and Power vs. Q) at constant speed.

- Calculate the Manometric Efficiency and Overall Efficiency of the fan.

- Study the effect of outlet throttling (system resistance) on fan performance.

Performance Measurement

- Measurement of Static Pressure and Velocity Pressure using Pitot tubes and manometers.

- Determination of Volume Flow Rate using an orifice plate or suitable flow nozzle at the fan inlet/outlet.

- Calculation of the Air Power (output) and Shaft Power (input).

- Plotting the best efficiency point (BEP) for the fan under test.

Panel and Instruments / Components

- Centrifugal Fan Unit: Dynamic machine designed for large volume air movement at relatively low pressure increases.

- Variable Speed Drive (VSD): Allows the speed (N) to be precisely varied for generating multiple characteristic curves.

- Instrumentation Panel: Digital displays for RPM and Motor Power Input (V & I).

- Pressure Measurement: Inclined/U-tube Manometers or pressure transducers for measuring static and differential pressures.

- Airflow Measurement: Orifice plate or flow nozzle mounted in the duct with pressure taps.

- Throttling Mechanism: Adjustable damper or valve on the fan outlet to vary the system resistance.

Specifications

| Feature | Detail |

| Machine Type | Centrifugal Fan (Air Blower) |

| Max Static Head | Typically up to 100-200 mm of water column |

| Flow Measurement | Orifice Meter/Flow Nozzle |

| Pressure Measurement | Manometers (Inclined/U-Tube) |

| Drive System | Variable Frequency Drive (VFD) Motor |

| Construction | Blue Powder-Coated Frame, Clear Ducting for visualization |

Note: Customized specifications, accessories, panel instruments, and LabVIEW software available on request.